Spoil Boards, Hold-downs, and Dust Collection

Comments Off on Spoil Boards, Hold-downs, and Dust Collection Holding the part to be cut firmly and without movement or vibration is often the biggest challenge faced when cutting on a CNC. Chatter, movement, premature tool wear, tool breakage, poor edge finish, and chipping are the result of inadequate hold-down. How well you can hold the part is perhaps the biggest factor in how fast you can cut.

Holding the part to be cut firmly and without movement or vibration is often the biggest challenge faced when cutting on a CNC. Chatter, movement, premature tool wear, tool breakage, poor edge finish, and chipping are the result of inadequate hold-down. How well you can hold the part is perhaps the biggest factor in how fast you can cut.

There is a lot of information on building dedicated spoil boards and jigs so we cover the basics in our free downloadable CNC Manual, and will provide an excerpt here. For the rest of the article, refer to the CNC Manual pages 13, 14, 15.

Some factors to consider include:

• Some CNC operations are best suited to using flow through or suck through vacuum systems. Particularly well-suited for cutting large parts and sheets of material, these types of routers utilize replaceable spoil boards—so called because they are underneath the material to be cut and are cut and “spoiled” during machining. The spoil board can then be resurfaced and used again, sparing the router table underneath from damage. These types of systems are easy to use and require minimal maintenance. Using low (LDF) or medium density fiberboard (MDF), both sides are machined level using a large “fly” cutter to remove any imperfections or coatings. Vacuum is evenly distributed to the entire surface of the table. Air loss from the sides can be minimized by using rubberized or latex paint. Areas not to be used should be sealed with sheets of laminate, plastic, or other non-porous materials. Grooves resulting from the cutting process can cause vacuum leakage when cutting a variety of patterns. Resurfacing the spoil board should be done regularly.

• Smaller or more intricate parts are better suited to dedicated spoil boards due to vibrations and part movements. Cutting small parts can be challenging since a larger volume of air is lost due to the number of channels cut between parts. As more parts are cut, more air pressure is lost, resulting in vibration and part movement.

• Leaving a thin skin (onion skin) or programming tabs at certain points can help to hold small parts together but require a secondary routing or sanding operation.

• Use dedicated spoil boards for recurring part runs. Taking the time to make a proper spoil board will pay for itself by allowing faster feed rates, giving you a better finish, and prolonging tool life.

To continue, refer to the CNC Manual pages 13, 14, 15.

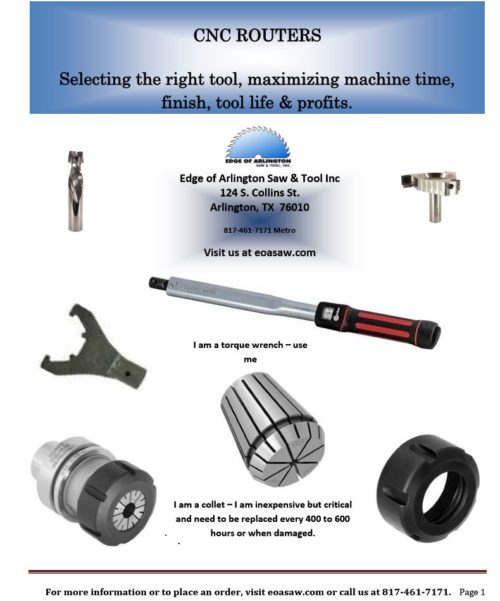

• Over-tightening of the collet and collet nut is a common mistake. Most operators assume that the tighter the better – this is not true and can lead to premature tool and collet wear and tool breakage. Collets are the most misunderstood and overlooked part of the CNC, often the cause of poor finish, short tool life, and unnecessary machine wear. Collets are made of spring steel and are subject to distortion when put under undue pressure. It is highly recommended that collets be tightened to manufacturers’ specifications with the use of a torque wrench

• Over-tightening of the collet and collet nut is a common mistake. Most operators assume that the tighter the better – this is not true and can lead to premature tool and collet wear and tool breakage. Collets are the most misunderstood and overlooked part of the CNC, often the cause of poor finish, short tool life, and unnecessary machine wear. Collets are made of spring steel and are subject to distortion when put under undue pressure. It is highly recommended that collets be tightened to manufacturers’ specifications with the use of a torque wrench There are a lot of different geometries involved in making a router bit—clearance angles, grinding angles, hook angles, axle angles, side clearance angles, radial clearance angles, and side rake. For the purposes of our discussion we will only talk about the basics.

There are a lot of different geometries involved in making a router bit—clearance angles, grinding angles, hook angles, axle angles, side clearance angles, radial clearance angles, and side rake. For the purposes of our discussion we will only talk about the basics.