Can’t find a stock tool for your cutting situation? Edge of Arlington can help you with a unique cutting solution tailored to your particular needs. We are experienced in a wide variety of materials, applications, and processes. We have on-site manufacturing capabilities and represent some of the finest industrial manufacturers in the world.

Purchasing custom tooling doesn’t have to be complicated, intimidating, or mysterious. It is really a simple matter when broken down in steps:

1) Gather information

The more information we have to work with, the better. Many times the type of tool that we will design will be dictated by the machinery to be used, material to be cut, ability to hold the material, etc.

2) Supply profile to be cut

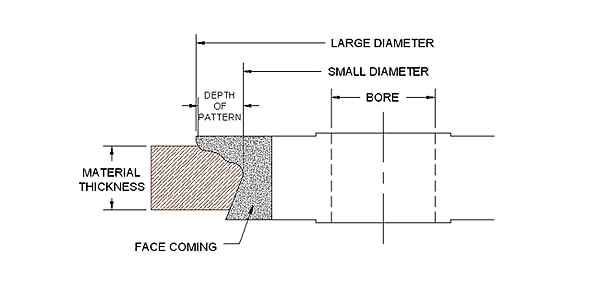

Please supply a wood sample, dimensional drawing or .DFX file of the profile to be cut. If the profile is too large it may be necessary to break up the cut, utilizing multiple tools.

3) Drawing approval

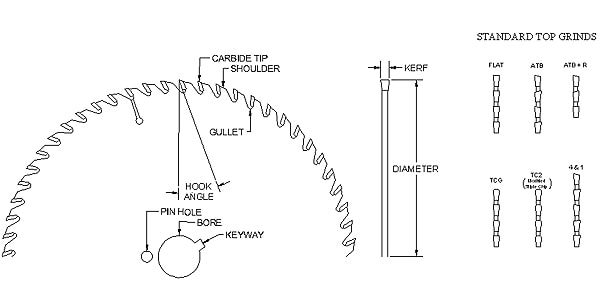

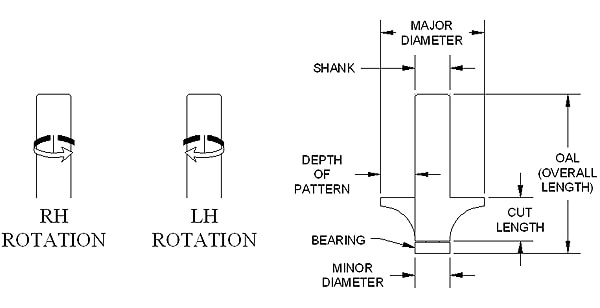

Once we have all the information and your profile, we will supply a detailed print for your final approval. Please make sure that you verify the information closely as custom tooling is not returnable after approval. The print will have a unique identifying number for easy re-ordering and will include details, such as tool rotation and orientation.

4) Tool delivery

Delivery of custom tooling can vary greatly from a few days to many weeks. Some processes, such as heat treatment or grinding diamond, cannot be sped up. We try to work with our customers to deliver in the time frame needed. We have on many occasions performed near miracles, such as overnight delivery; however, that can come at great cost and is not always possible.

There are too many cutting situations to try to cover all possibilities. Please fill out the request for quote form with your contact information and as much other information as you can supply. We will contact you and ask specific questions as needed. Below are examples of basic information that we will need to collect: